TAKE HOME MESSAGES

- Regularly weighing lambs and assessing feed quality and availability ensures lamb growth rates remain high and profitable.

- Daily weight gains of 180 to 200g/ day can be achieved with the right feed mix.

- Lambs which finish early produce less methane (a GHG) relative to lambs with a low growth rate.

BACKGROUND

BCG and CSIRO, with the support of a Department of Agriculture, ‘Action on the Ground’ grant, have spent two seasons working with farmers from the Birchip and Charlton regions trialling different methods of finishing lambs. The trials took place while the current livestock management systems on each farm continued without change or interruption. The trials compared standard farmer practice with a range of alternative feeding regimes to see whether growth rates could be improved and at what cost.

When lambs are finished earlier, the total amount of methane (a greenhouse gas) emitted per kilogram of meat produced is less than when lambs take longer to reach sale weight.

AIM

To demonstrate on-farm practices and technologies that improve lamb growth rates, reduce finishing times of lambs and reduce ‘whole of life’ methane emissions.

METHOD

In collaboration with landowners, farm trials were carried out on four mixed farming (sheep and cropping) enterprises within an 80km radius of Birchip, Victoria. Various aspects of each farms’ lamb finishing program were evaluated to determine the benefits of improving nutrition either in the paddock or containment area to promote earlier turnoff of lambs to market. Four farm trials from the 2013/2014 summer are reported in this manual.

Trial treatments are detailed for each farm separately.

Trial lambs were background fed grain/pellets for a minimum of 10 days before treatments were implemented.

Each treatment group consisted of approximately 60 lambs of mixed sex and within a weight range as close as possible to +/- 5kg. Electronic ear tags were used to identify individual lambs and so their growth rates could be monitored. Trial lambs were weighed a minimum of five times, at approximate fortnightly intervals, throughout the trial period. The end of the trial was determined when the producer deemed that lambs had reached the desired liveweight (LW) target for his preferred market. Consequently, final LW and trial durations varied between properties.

The quantity and quality of paddock stubble and grain feed were measured throughout the trial. Stubble dry matter (kg/ha) and spilled grain counts were measured from both the header row and inter-row using 10 quadrats, GPS referenced on a transect across each paddock.

Commercial pellets used were CopRice Lamb Finisher 16% formulation, donated by CopRice Pty. Ltd., Tongala, Victoria.

Feed costs were calculated for each property based on a) total trial duration and b) feed consumed to reach a LW target of 50kg. Feed prices used to calculate feed cost are detailed in Table 1.

Table 1. Prices used to calculate feed costs for all properties.

RESULTS AND INTERPRETATION

Some of the problems experienced in running these trials in both seasons, along with the resulting data, highlighted the many management issues that can affect the growth rate and subsequent time taken for lambs to reach sale weight. With different selling markets now available, the market weight range is a major consideration when finishing lambs.

High temperatures experienced by trial lambs in mid and late January, early February and mid March in 2014 potentially affected their productivity due to heat stress and their ability to access shade and water.

Farm 1

Standard practice at Farm 1 was to graze lambs on stubble, supplementing them with trail fed grain as required. This trial compared this practice with two other feeding methods – a self-feeder providing ad-lib grain placed in a stubble paddock; and a self-feeder with ad-lib grain in a containment area, supplemented with hay. The grain supplied in this trial was a barley/lupin/oat ration mix (50:30:20). Only the amount of feed and availability differed.

Treatments

- Trail fed – West paddock: this involved trail feeding the grain mix at approximately four day intervals, as per farmer practice, on a wheat stubble with approximately 72kg/ha of spilt grain available at the start of grazing.

- Self-feeder – Barrel paddock: this treatment saw a self-feeder containing the grain mix, filled as required and placed in a wheat stubble paddock. Very little spilt grain was available, as the Barrel paddock had been grazed the pre-trial and was used to background the lambs.

- Feedlot – a self-feeder containing the grain mix was placed in a containment area where some shade was provided. The self-feeder was filled as required and a supply of cereal/grass hay was also made available.

On 9 December 2013, 206 wether first cross lambs were selected. These lambs were placed in the Barrel paddock with no supplementary feed for 15 days. Background feeding began on 24 December 2013 and the lambs were trail fed a grain mix for 24 days.

On 17 January, 2014 the lambs were split into the three treatment groups. The self-feeder group remained in the Barrel paddock.

At the start of the trial period there was very little grain remaining on the ground in the Barrel paddock (Figure 1) so the self-feeder lambs relied mainly on supplementary feeding. Stubble feed tests indicate that over time the fibre increased while the metabolisable energy (ME), crude protein and dry matter digestibility (DMD) decreased (Figure 2), indicating a level of selective grazing by the lambs.

Figure 1. Grain and straw available to lambs in the Barrel paddock over the trial period. Note: the lambs were background fed in this paddock until 17 January 2014 when the trial commenced.

Figure 2. Stubble feed tests for the Barrel paddock (the trial commenced on 17 January 2014).

The trail fed lambs were grazed in the West paddock; a wheat stubble with 72kg/ha available split grain at the commencement of the trial. The stubble measurements indicated a similar amount spilt grain and stubble available at the end of the trial (Figure 3). The large variability in spilt grain across the paddock and the size of the paddock meant we were unable to measure the amount of feed the trail fed lambs used from the paddock.

Figure 3. Grain and straw available to lambs in the West paddock over the trial period.

Liveweights

Liveweights (LW ± s.e.) were recorded on 11 occasions during the trial (Figure 4). During the 109 days of the treatment period, the Self-feeder group had an average daily weight gain (ADWG) of 153g/ day; the Feedlot group 125g/day; and the Trail fed group 115g/day. Consequently, the Self-feeder group finished the trial significantly heavier than the Trail fed and Feedlot groups, which were not significantly different from each other.

Figure 4: Mean liveweight (± s.e.) for the three treatment groups on Farm 1.

Table 2. Feed amount and costs for trial period and to reach a sale weight of 50kg liveweight.

*Days to reach sale weight of 50kg calculated using ADWG for the final LW period. **Significant differences ( P<0.05) are denoted by different letters.

The Self-feeder group reached the target sale weight of 50kg in 109 days, gaining 16.7kg and costing $24.64 in feed (Table 2). If the Trail fed and Feedlot treatments continued to grow at the same rate with the same feed intake, at their final weighing the Trail fed group would take a further 29 days, but cost $4 less and the Feedlot group would take an extra 17 days, costing $4.60 more to reach 50kg.

The lower performance of the feedlot group in the early part of the trial indicates the difficulty in managing animals in confinement, especially during periods of high ambient temperature.

Farm 2

On Farm 2, standard practice was to graze lambs on stubbles supplemented with a grain mix in a selffeeder and/or finished in a containment area if required. The trial compared lamb performance when using this practice with the performance of two containment groups – one fed a grain ration and the other fed CopRice pellets.

Treatments

- Stubble – lambs were a barley/wheat grain mix ration (90:10) from self-feeder in the House paddock which contained wheat stubble. Later medic hay was supplied, after which the group were moved to the feedlot for finishing on a barley/peas/wheat grain mix (80:10:10) and medic hay.

- Grain mix – lambs were fed a barley/peas/wheat grain mix (80:10:10) in a containment area. In addition, hay was supplied (wheaten, barley or medic).

- Pellets – CopRice finisher pellet were fed to lambs in a containment area. In addition, hay was supplied (wheaten, barley or medic).

Lambs were selected on 23 December 2013 and run as a single mob without supplements at the commencement of the trial. Background feeding began on 20 January, 2014 for a period of 49 days. During this time the lambs received a ration of barley and CopRice lamb finisher pellets (50:50) to develop their rumen fully; this was initially trail fed but then a self-feeder was employed to train animals going into a containment situation. Liveweights were recorded on eight occasions over the duration of the trial.

The House paddock wheat stubble had very low grain levels; 6.8kg/ha at the commencement of the trial (Figure 5). This paddock was used for the Stubble treatment and although spilt grain levels slowly reduced over the trial period, lambs needed to work quite hard to utilise anything from this paddock and this was reflected in their initial low growth rates (Figure 6).

Figure 5. Grain and straw amounts in the House paddock.

Lambs were split into treatment groups on 27 February. Lambs in the Grain and Pellet groups were placed in containment areas and fed from self-feeders and with hay available. The Stubble group remained in the House paddock with a self-feeder and were fed a grain ration of barley and wheat (90:10), as per standard farmer practice.

Due to the low growth rates being achieved by the Stubble group, the lambs were provided with medic hay on 15 April and were moved from the stubble paddock to a containment area on 4 May. They were then fed the same ration as the Grain group for the last nine days of the trial. The Stubble group would never have reached sale weight without the introduction of a higher energy food source.

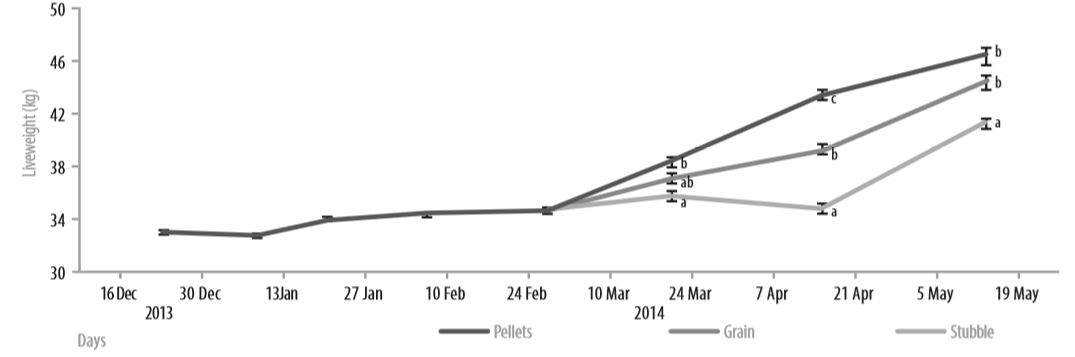

Figure 6. Liveweights (±s.e.) for the treatment groups on Farm 2. Note: from 15 April the Stubble group were provided with medic hay and on 4 May were moved into a containment area and fed grain and hay.

Figure 6. Liveweights (±s.e.) for the treatment groups on Farm 2. Note: from 15 April the Stubble group were provided with medic hay and on 4 May were moved into a containment area and fed grain and hay.

Calculation of lamb performance to 50kg was based on feeding rates and average daily weight gain (ADWG) between 15 April and 13 May. The ADGW for this period were 236g/d for the Stubble group (after moving to the feedlot), 189g/d for the Grain group and 113g/d for the Pellet group.

Table 3. Feed amount and costs for trial period and to reach a sale weight of 50kg liveweight.

*Days to reach sale weight of 50kg calculated using ADWG for the final LW period. **Significant differences ( P<0.05) are denoted by different letters.

Based on the feed offered and growth rate for the final growth period (Figure 6), the Grain and Pellet groups would take about one week less to reach a 50kg sale weight compared with the Stubble group (Table 3). The Stubble group growth rate increased significantly once medic hay and grain were supplied, and the lambs were subsequently moved to the containment area. The feeding cost for the Stubble group was $20/hd, while the cost to feed the Grain group was $32/ hd. The ADWG for the Pellet group in the final period was quite low, while the feeding rate was high; this skewed feeding costs to $50.

Farm 3

Standard practice on Farm 3 was to graze lambs on cereal stubble and to divide them into a heavy mob for finishing early and a lighter mob for finishing later. The intention behind this practice was to spread the price risk when accessing the market. This trial compared the performance of later finishing lambs grazing cereal stubbles only with the earlier finishing lambs that were first grazed on cereal stubble and then moved to a pulse stubble.

Lambs were weighed and divided into two groups (Early and Late) and electronically tagged. Both groups were run as part of larger mobs (approximately 300 head) and the heavier lambs were sold off as they reached sale weight. Farmer practice of observing lambs and stubbles was used to decide when the mobs would be moved to fresh stubbles.

Figure 7. Liveweights (±s.e.) for the treatment groups on Farm 3.

Liveweights

After 56 days some Early group lambs had reached sale weight and were sold. At the time, the average liveweight for the Early group was 47kg and the Late group 43kg. It would have taken the Early group a total of 67 days to reach the target sale weight of 50kg, while the Late group would have taken 80 days, or two weeks longer.

This trial highlighted the need to monitor and measure lambs and feed availability in stubbles, as both groups lost weight when the stubbles were depleted as well as during the hot period in mid January.

While the practice of running Late lambs suits the producer’s risk management strategy, shifting this group to the pulse stubble paddock sooner would have resulted in a similar performance to the Early group, at least while spilt grain was available.

Farm 4

Standard practice on Farm 4 was to graze stubbles while the feed availability was good and to then supplement the lambs with grain and/or vetch hay. This trial compared three treatment groups. Prior to the commencement of the trial, backgrounding was carried out over a 10-day period with all sheep run as a single mob. During this period the sheep received a ration of barley and pellets (50:50) which was initially trail fed on a dry pasture paddock. Liveweights were recorded eight times over the 118-day duration of the trial (Figure 8).

Treatments

- Paddock – good quality vetch hay was fed in the paddock with very little other feed available. From May 13 to 27 the lambs were also trail fed grain (1kg/hd/d) and from 27 May to 10 June lambs were moved to the containment area and fed vetch hay ad-lib and a grain mix at rates similar to the grain group.

- Grain – this group was fed a barley/lupin ration (90:10) with straw available. Vetch hay was offered for the first 10 days after introduction to the feedlot.

- Pellets – lambs were fed a CopRice lamb finisher pellet with straw available. Vetch hay was offered for the first 10 days after introduction to the feedlot.

Figure 8. Liveweights (±s.e.) for the treatment groups at Farm 4. Note that on 13 May the paddock group were trail fed grain and on the 27 May the lambs went into the feedlot for the last two weeks.

Liveweights

The manager of Farm 4 decided to continue this trial until the lambs reached 60kg, which for all treatments took about the same time (118 days). There was no significant difference in the final liveweights when the three groups were compared, but the growth paths they followed were quite different (Figure 8). The Paddock group grew faster than the confinement groups for the first six weeks, but growth rate was almost nil during April-May as the lambs could not physically eat enough vetch hay to meet their daily energy requirement for growth (this period was artificially extended by the producer to demonstrate the impact of physical limitation to intake).

When grain was introduced on 13 May, lamb growth rate increased significantly. Introduction of the grain supplement at the first sign of slowed weight gain would have reduced time to finishing and the time it took to meet the 50kg target.

The LW for the Pellet group was significantly higher than the Grain group between 18 March and 29 May, suggesting the pellets provided a more balanced diet. The higher ADWG for the Grain group in the final period was the result of higher grain consumption.

Overall, the feed cost for the Grain group was $41.70. The costs for the Paddock and Pellet groups were 27 per cent and 56 per cent higher respectively. The cost for the Paddock group includes 35 days of feeding with no LW gain.

Performance to 50kg

The Pellet group grew 27 per cent faster than the Grain group (199g/d v. 156 g/d), but cost $3.56, or about 11 per cent more. The Pellet group reached the 50kg target sale weight in 57 days at a cost of $34.71; the Grain group took 73 days and cost $31.15.

The Paddock group took the longest and cost the most (83 days @ $44.12) because of the delay in providing additional supplements.

The cost to fatten lambs from 50kg to 62kg changed between groups. To reach 50kg LW, the Grain group cost an additional 34 per cent to gain the final 12kg LW, the Paddock group an additional 20 per cent and the Pellet group an additional 88 per cent. The higher cost for the Pellet group suggests that the ration formulation in the pellets is probably better suited to younger, faster growing animals (35-45kg LW) than the heavier LWs seen at the end of the trial with higher maintenance energy requirements and lower efficiency of energy use for growth.

Table 4. Feed amount and costs for trial period and to reach a sale weight of 50kg liveweight.

*days to reach target weight were calculated using ADWG measured for the duration of the trial

Methane production

Methane (CH4) production from lambs is influenced by:

- what they eat

- how much they eat

- the length of time that they eat.

The number of days a lamb takes to reach a target liveweight is the major contributor to methane (CH4) production. The Grazfeed simulation model illustrates how feeding lambs high quality hay, as opposed to low quality stubble with a grain ration, increases the methane a lamb produces per day, but halves the time it takes to grow, therefore reducing its overall methane emissions (Table 5).

Table 5. Grazfeed simulations for a Merino lamb (at 30kg) to reach a liveweight of 40kg.

Methane emissions on the four trial farms

The number of days taken to reach the 50kg sale weight for the trial lambs varied significantly between treatments. The difference between the fastest and slowest treatment for each farm, and the additional methane produced, is shown in Table 6.

Table 6. Time taken to reach 50kg liveweight and additional methane produced on the four farms.

COMMERCIAL PRACTICE

The main lessons from the two years of trial work (aimed at increasing lamb productivity and reducing methane emissions) were to:

- regularly monitor lambs by weighing or condition scoring, and monitor feed availability in stubbles to prevent lambs going backwards

- supplement energy early to avoid flat lining growth; lambs on ‘hay only’ cannot physically eat enough to maintain growth

- know what, and how much, you are feeding; weigh, feed test and work out a balanced ration for growth not just maintenance

- trail feed lambs every one or two days to reduce the risk of acidosis

- take into account that the amount of spilt grain in stubbles can be substantially limited by the use of new harvesters, but may vary by operator (assume five per cent of mean yield)

- make sure there is plenty of shade and fresh water available at all times, but especially during very hot weather, and in containment areas

- understand that one month of extra feeding to reach the target sale weight will produce about 33 per cent more methane per lamb.

ON-FARM PROFITABILITY

Supplementary feeding without improving growth rates can be costly and time consuming.

The cost of feed and the time taken to reach the target sale weight of 50kg varied between farms and treatments.

Farm 1

Although the Trail fed group cost $4/hd less to feed than the Self-feeder group, they took a further 29 days to reach 50kg. If labour costs were included, the Self-feeder group would be the most efficient and cost effective group.

Farm 2

The compensatory growth of the Stubble group, once given hay, together with a grain mix, meant they took one week longer to grow to 50kg than the other groups.

The low cost ($20) of feeding the Stubble group compared with the Grain group ($30) and the Pellet group ($50) indicated this was the most efficient practice, but the pellet feeding rate and ADWG in the final period skewed these results.

Farm 3

There was a difference of 13 days between the time it took for the Early and Late groups to reach 50kg, but neither had a calculated feed cost as they were both grazed on stubbles.

The labour cost and added risk were the two major differences between these two groups. If both groups had been shifted to new stubbles, or had supplementary feed been supplied before they lost weight, both groups should have finished earlier.

Farm 4

The Pellet group took 16 days less than the Grain group to reach 50kg and cost $3.50 more in feed. The Paddock group took 26 days longer and cost $10 more, but this was influenced by the farmer’s timing in introducing grain supplements.

The extra labour costs and risk associated with a longer growth period should outweigh the extra cost of Pellets to reach $50/kg. The costs changed significantly when the lambs were grown to 60kg with the Pellet group costing $23 more in feed than the Grain group and the Paddock group being in between.

ACKNOWLEDGEMENTS

The project is supported by a Department of Agriculture – Action on the Ground Grant (AOTGR1-149) and by CopRice Pty Ltd, through the donation of all finisher pellets used in trial.