Take home messages

- Pulse seed coating and zinc foliar applications had no impact on final grain yield.

- Gibberellic acid (GA) did not benefit the hay or grain yield of vetch, but in lentils there

was a significant yield loss, even though harvestability was potentially improved. - Growers need to make sure that every dollar spent provides a positive return to their bottom line.

Background

The number of products out there claiming benefits to crop production is astounding. Trying to keep up with those worth using, while discarding the ones that, despite their marketing pledge, have no real benefit, is a constant challenge. Nevertheless, growers need to make sure that every dollar spent provides a positive return, otherwise it is nothing more than an added cost in a game that already has narrow margins.

This season, a prominent agricultural supplies company exerted a pretty strong push for a new pulse seed coating product with claims that it improved early lentil crop growth and nodulation. Being a relatively low cost product, use was quite widespread and trials were established to compare the effect of this product with in-crop zinc foliar applications.

In addition, two trials were set up to look at the use of gibberellic acid (GA) in lentils and vetch.GA is a hormone naturally found in plants that stimulates stem elongation and drives the flush of growth that commonly occurs as the weather warms up in spring. It can come in many forms and can be used to boost growth evenly throughout a plant. It has been observed that GA plays a role in the stimulation of flowering and reproductive growth but there are still questions around the timing of GA application and its ability to have a significant impact on crop growth and yield.

Approximately 10 years ago, farmers explored opportunities to use GA in crops such as lentils to boost growth, largely in an attempt to improve harvestability, but progress in this space has been slow.

However, in 2015 some application occurred, photos appearing on social media and farmers dabbled with GA once again in a season where the full benefits were possibly difficult to achieve.

Local sales representatives whose companies contain GA in their product range seemed to find one thing in common; lots of anecdotal evidence and photos, but no data to support the claims specifically in grain legume crops such as lentils.

This trial was set up as a pilot to test a couple of application timings and their influence on crop performance, looking at it from both a yield (hay or grain) and an economic perspective. Although the cost of GA is vastly cheaper than 10 years ago, tight margins mean that even small inputs need to be scrutinised to ascertain their benefits.

Aim

To determine if seed dressings or zinc applications can improve lentil growth and yields; and if the use of GA can improve lentil and vetch growth, biomass production and yield.

Paddock details

| Location: | Warmur |

| Annual rainfall: | 444mm |

| GSR (Apr-Oct): | 371mm |

| Soil type: | Clay loam |

| Paddock history: | 2015 fallow |

Trial detials

| Crop types: | PBA Jumbo 2 lentils, Rasina vetch |

| Treatments: | Refer to tables 1 and 2. |

| Target plant density: | Lentils – 90 plants/m2, vetch – 60 plants/m2 |

| Seeding equipment: | Knife points, press wheels, 30cm row spacing |

| Sowing date: | 4/5 May |

| Replicates: | Four |

| Harvest date: | 9 December |

Trial inputs

| Fertiliser: | Granulock Supreme Z @ 50kg/ha at sowing |

| Herbicide: | 4 May Trifluralin @ 1.5L/ha + Simazine @ 0.5kg/ha 26 June Clethodim 240 @ 0.5L/ha + Haloxyfop @ 0.1L/ha+ Uptake @ 0.5% + Liase @ 2% |

| Insecticide: | 30 October Alpha-cypermethrin @ 100mL/ha |

| Fungicide: | 23 August Barrack @ 1.5L/ha

18 September Barrack @ 1.5L/ha + Spin Flo @ 500mL/ha |

| Seed treatment/inoculant: | Pulses were inoculated with Group EF granular inoculant at sowing. |

Method

Three replicated field trials (two for lentils (seed dressings and GA), one for vetch) were sown using a complete randomised block design. Treatments used for the seed dressings and zinc foliar trial are listed in Table 1. Treatments carried out in terms of GA application are outlined in Table 2. The product used for this trial was GALA™ growth regulator.

Assessments carried out in the seed dressings trial included establishment counts, early growth as assessed by Normalised Difference Vegetation Index (NDVI) and biomass assessment at flowering.

Assessments carried out in the GA trials during the season included height assessments approximately two weeks after the last GA application (mid-flowering), biomass cuts at flowering and lowest pod assessment in the lentils at maturity. All trials were harvested for grain yield. Grain size, as measured by 1000 grain weight, was calculated.

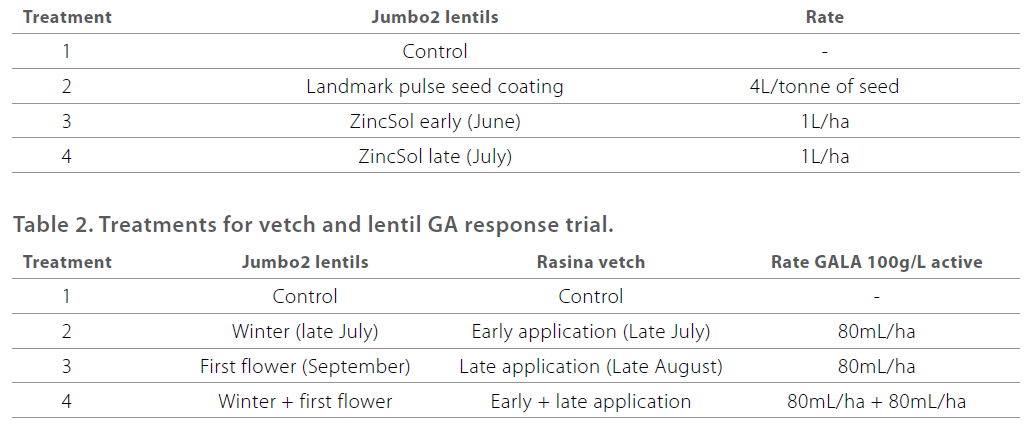

Table 1. Treatments for lentil seed coating and zinc foliar trial.

Results and interpretation

The season at Warmur was exceptional in terms of rainfall but this did present some challenges to the pulse trials located at the site. Continued rainfall, meant there were times when the cops had to deal with waterlogging. Diseases presented a challenge, particularly botrytis grey mould in the vetch, and the abundance of growth also made harvest challenging in the vetch. The lentils on the other hand fared reasonably well, with the variety chosen standing up to the season better than other varieties may have (anecdotal from farmer discussion).

The results in this section will be broken into the different trials for ease of reading and interpretation.

Seed dressings and zinc in lentils

Early in-crop assessments including establishment, early seedling growth and nodulation showed no difference as a result of using the pulse seed coating. The reason behind this lack of early result is difficult to explain as the full workings of the product are not well understood in this situation. Given this is one trial in one season, it is hard to determine if soil type played a role and whether a different soil, with more constraints (ie. a low nutrition sand) would have a different result.

Using the pulse seed coating or ZincSol foliar sprays did not result in significantly greater yields at 95 per cent confidence (Figure 1).

Figure 1. Mean lentil grain yield (t/ha) of seed treatments and foliar applications at Warmur, 2016. Stats: NS (P=0.103), LSD=0.103t/ha, CV=3.9%.

Gibberellic acid in vetch

The use of GA in vetch was largely confounded late in the season by disease that under the dense canopy (10-12t/ha DM), was very difficult to control. Prior to disease setting in however, some visual observations were seen in and correlated with measured assessments. These are discussed below.

NDVI measurements taken 21 days after the first GA application showed that the plots that had been sprayed at the first application timing were actually returning as slightly lower NDVI than the unsprayed plots, despite a positive visual growth difference in these treatments (Figure 2). This corresponds with the understanding that GA, and the sudden growth burst it motivates, can result in the plant looking paler and more spindly for the period of time that the GA is working. This is due to the rapid growth not always being met by an adequate supply of nutrition, creating a washed out effect. It is also why in grass dominant pasture systems it is recommended that GA is applied with nitrogen. Given the lack of additional N required in a well nodulated legume crop, the applicability of this practice to vetch or lentils is probably low, but could be worth investigating.

Figure 2. Mean NDVI of sprayed and unsprayed 21 days after first application of GA.

Stats: P=0.01, LSD=0.015, CV=1.6%.

As mentioned, the presence of disease later in the crop, and difficulty sampling and harvesting plots that were very low and tangled together, meant no differences were noted in flowering biomass (which would simulate hay cut timing), yield or grain size.

Gibberellic acid in lentils

The use of GA in lentils provided some interesting results. NDVI measurements taken through the season did not show the same effects that were present in the vetch, although crops again appeared slightly paler and more wiry after GA was applied at both timings. With lentils a lighter green colour compared to vetch, identifying any effect would be more difficult to pick up through NDVI which essentially measures ‘greenness’.

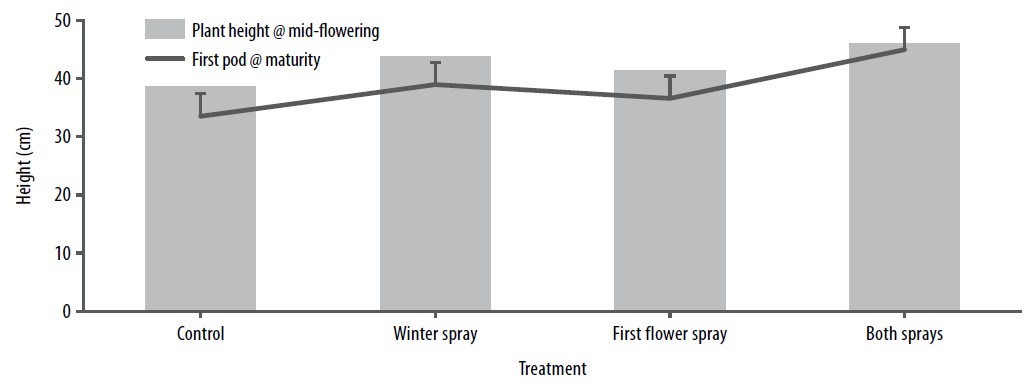

Plant height measurements taken at flowering followed a stepwise pattern that aligned well with growth response created by GA application. Earlier application timings had a more pronounced effect, with early sprayed treatments being generally taller. However, when the data was analysed it fell short of being significant (P=0.088) at 95 per cent confidence (Figure 3). Biomass taken at flowering despite these height fluctuations, showed no differences.

First pod height was significantly affected by GA. Plants that underwent the winter spray, first flower spray and both spray treatments set their first pod at 5.2cm, 3cm and 11.3cm, respectively, which was higher along the stem than the control. This difference shows that there has been considerable stem elongation as a result of GA application, and that the earlier spray timing (or the double spray) had a bigger effect on the setting height of the lowest pod than the flowering spray alone.

It should be noted that this doesn’t indicate the harvest height that can be used, as lentils late in the season tend to bend over (lodge) a little meaning harvest height is lower than when the plant is outstretched. Despite this, it is plausible to conclude that GA could improve harvestability as it would be easier to get crop lifters under the main podding area with a longer main stem to work with. This benefit is likely to be increased in crops where retained stubble is present that can also act as a trellis to the developing lentil plant.

In terms of harvestability this season, crop height in all treatments was adequate to allow good pickup of lentils and minimal losses.

Figure 3. Mean plant height (cm) at mid-flowering, and location of lowest pod (cm) on main stem of an outstretched plant. Stats: Plant height NS (P=0.088), LSD=5.83cm, CV=8%; Lowest pod P=0.003, LSD=4.09cm, CV=6.2%. Note: First pod at maturity was measured by extending the plant and measuring the distance from the ground to where the first pod was set, not the harvest height of the first pod.

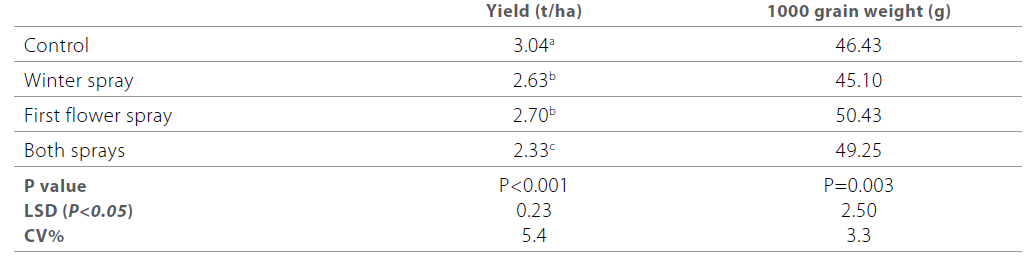

Converse to crop height, there was a highly significant yield penalty from using GA at all timings. This yield penalty has to raise questions about the perceived benefits of GA. Specifically, are the height benefits offered by GA worth chasing, considering (in this trial) there was up to a 0.7t/ha penalty when compared with the control (Table 3)?

The reasons behind this result are difficult to pin down. However, suggestions include:

- The product is not suited to a bumper year where moisture to support growth was unlimited, but

nutrition may be limited. It therefore may have a better fit in an average season. - The season wasn’t particularly cold, so crop growth went into overdrive in the presence of GA, putting the crop into a position where it had exhausted available nutrition by the time it reached flowering. This hypothesis is supported by the fact that the yield penalty was worse in treatments where an early application took place, or two applications occurred.

In addition to this, it was interesting to note that the flowering application did not aid higher pod set or grain set. However this was not formally measured and is just assumed by the yield response collected at harvest.

According to 1000 grain weight data (Table 3) it is possible that GA application at flowering influenced grain size, and this fits well with work in grape production where GA is used to produce larger grapes. So it could be that it has a fit for this purpose as well, however the yield penalty from using the product at all in this season overshadows any seed size benefit that could change market access.

Table 3. Mean lentil yield (t/ha) and 1000 grain weight (g) as influenced by treatment.

Commercial practice

Trials of this nature look to prove or dispel marketing myths and see if products can really live up to the performance expected from them, because at the end of the day, every dollar counts, regardless of how insignificant it may seem in the scheme of things.

In 2016 at Warmur, pulse seed coating or zinc foliar sprays offered no significant yield benefit, and therefore can only be considered a cost to the system. However, in different circumstances or in soil types where background levels of the components found in these products may be lacking, the seed coating or zinc application may have had a different effect.

Nevertheless, if a grower is looking to use such products for the first time, they should always make sure they have some untreated crop in the paddock as well so they can make their own assessment of whether it works or not.

Similarly, the use of GA in vetch did not offer benefits that carried through to a time when hay cut would have occurred. It is likely that this was because the crop had caught up by this stage, so the benefit of the product was lost. It also had no benefit to grain yield.

These results need to be kept in context for this trial however, as disease did prove difficult to manage this season in this variety, and is likely confounding the results. In light of this, further work is warranted.

GA in lentils, on the other hand, produced some mixed results. If the motivation of the grower is to improve crop height for harvest benefits, it could have a good fit as it increased both crop height and position of the lowest pod on the main stem.

However, the yield penalty is a huge concern with 300-700kg/ha being the cost of using GA in 2016 this site. Growers would also be aware that the effectiveness of newer headers to harvest low crops is much better than even a few years ago, and varieties we have available are much more erect than those we may have become frustrated with in the past.

To be fair, it would be interesting to test GA in lentils in different seasons, as this season was

exceptional and probably saw different results to what may have been expected. But at the same time, if it doesn’t work in a good year, it’s hard to see big benefits in a more marginal year.

On-farm profitability

Putting three trials into a profitability spin is difficult to say the least, but some clear messages have come from the work.

To use pulse seed coating or zinc foliar sprays is a cheap option. Using the means presented in Figure 1 and applying economics to this situation could indicate a positive bottom line to using products like this. However, it needs to be remembered that the yields in this trial were not considered to be statistically different at 95 per cent confidence, and as such, returns are also not statistically different. This means that in this trial, at this site and in this season, the use of these products has been a cost to production. It may only seem like a drop in the ocean at around $1.50/ha, but if you add it up over your lentil program, it could quickly add up.

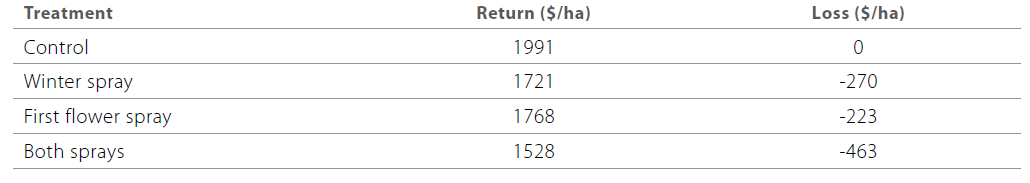

Using GA in vetch or lentils is a slightly more expensive exercise at around $8–$9/ha, plus application costs. This is vastly cheaper than 10 years ago, however again we have not picked up a benefit in vetch, and have actually incurred a significant cost to returns in lentils (Table 4).

Table 4. Returns and cost of using GA in lentils in 2016.

The key reason for using GA would be to improve harvestability, in which case there could be yield benefits and financial benefits as a result of getting more grain into the silo. But it appears the risk of yield loss is also quite large and requires more understanding over different seasons to ensure growers are not wasting their time on products that do not result in a better economic net position.

Acknowledgements

This trial was funded by BCG members through their membership.