BCG marked the end of an era this week (March 24 2015) when it officially retired its long running farming systems trial site at Jil Jil.

The BCG Farming Systems trial at Jil Jil (20kms north of Birchip) is the longest running field trial of its kind in Australia.

Since its inception, it has delivered a range of valuable research findings to Wimmera and Mallee farmers and played a small part in changing the farming landscape across the region.

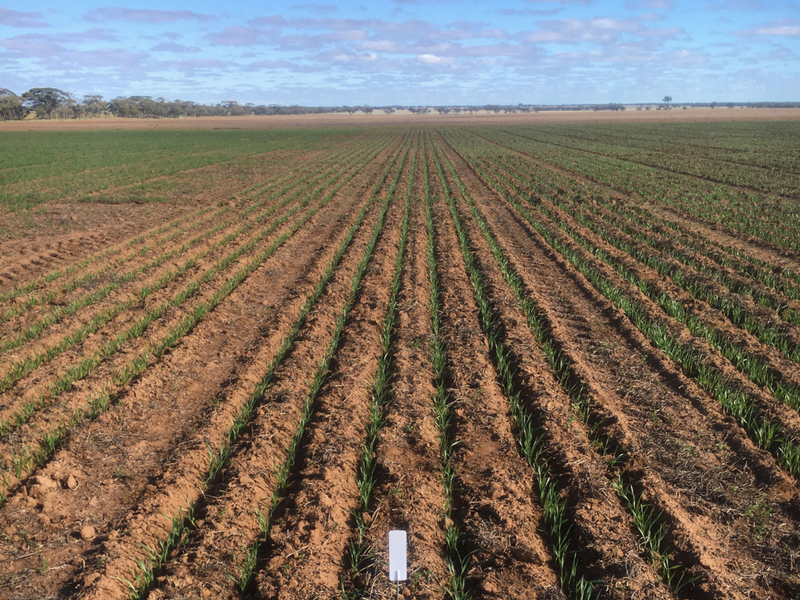

Motivated over a decade ago by grower interest and debate about new ways of farming, such as direct drill, continuous cropping, stubble retention and no-till, the trial looked to showcase how four distinct farming systems performed in the one paddock.

The initiative was driven by four local farmer ‘champions’ who dictated how each system should be managed.

In 1999 the farming systems site was established to determine which farming system was most profitable, productive and sustainable.

Systems represented were:

- ‘Fuel Burner’ – mainly cereals, the regular use of tilled fallow (commenced prior to harvest), low intensity livestock and full disturbance tillage at sowing;

- ‘Hungry Sheep’ – intensive cropping (mainly cereals), intensive grazing, winter lambing, grazing over summer to take advantage of stubbles and to control weeds, early sown cereal/pasture forage for feed and generally full disturbance tillage at sowing;

- ‘No-Till’ – minimum soil disturbance seeding (knife points, press wheels, 30.5cm row spacings) and no livestock. Initially this system included the high use of break crops but later cereals were predominant and some chemical fallow; and

- A ‘Reduced-Till’ system which took a flexible approach – tillage or full disturbance sowing, mainly chemical weed control, a mix of cereals, canola and other break crops and, in early years, some livestock over summer.

Specifically the project aimed to clarify the issues of:

- disease and weed seed-bank resulting from different farming systems;

- cultivation versus zero tillage;

- fallowing versus continuous cropping;

- the role of livestock in sustainable profitability;

- the stability of rotations which include pulses versus predominantly cereal based rotations ; and

- the effect of heavy grazing on soil structure and long term cropping productivity.

When the trial was established, it consisted of 32 plots, 1 to 1.4 hectares in size, with each of the systems replicated five times. An additional 12 ‘standard’ (control) plots were included in the plot design to determine whether there was any spatial variation in yield across the site.

The standard plots had a set rotation of fallow, wheat, field peas and canola with each phase of the rotation represented each year and plots replicated three times.

The 32 system plots were managed according to the direction of each of the champions who included Paul Barclay (Fuel Burner), Warrick and Ian McClelland (Hungry Sheep), Alan Postlethwaite, 1999-2009 and Cameron Warne, 2010-2014 (No-Till) and Brad Martin (Reduced-Till).

To identify the success of each farming system, the project attempted to integrate bio-physical and economic research into an analysis of whole farm outcomes. Initially, the main focus was to compare the practical implications of each rotation; economic viability and risk; soil-water relationships; soil biological activity; changes in weed type and weed populations; changes in disease levels; the dynamics of the soil nutrition store; and physical characteristics of the soil.

Analysis conducted on the farming system trial since 2000 demonstrated that no one system was more profitable than any other (2012 BCG Season Research Results pp. 171).

The take home message was that, in terms of profitability, it doesn’t matter which system you employ, provided you manage that system well.

However, over the last 15 years this isn’t the only thing the systems site taught farmers.

In its first decade of its operation the site endured some challenges, namely the Millennium Drought producing some of the driest seasons on record.

From these challenges the benefits of conserving soil water became clear, as did an understanding of soil type and the impact of sub-soil constraints on crop production.

The severe subsoil limitations discovered within the highly alkaline calcarosol soils at the site drove home understandings about the inability of such soils to support pulse and canola crops, particularly in dry seasons.

Hard lessons were particularly learned via the ‘No-Till’ system which suffered failed canola and pulse crops in the early years. However, this helped growers appreciate both the challenges of subsoil constraints and the value of a chemical fallow.

Once the ‘No Till’ rotation was altered to a continuous cereal with chemical fallow, performance results improved markedly, in 2005 producing the highest yielding wheat crop at the site (on a chemical fallow).

An analysis (2000-2012) of soil health across each of the farming systems also delivered some valuable learnings with results showing that systems which employ heavy grazing reduce the number of PSB in the soil compared with other systems, highlighting the need for more phosphorous (P) fertiliser than the other systems.

This research also showed that ‘No-Till’ systems are not conducive to the survival and reproduction of nitrogen (N) fixing bacteria in the soil and this may see a reduction in N mineralisation throughout the year (McClelland, 2012).

While the initial focus of the BCG Farming Systems site was to discover the most viable and sustainable farming system, along the way the site facilitated a range of investigations that have added to the collective knowledge of farmers in the Wimmera and Mallee.

In conjunction with the study of farming systems, the Jil Jil site hosted a long term investigation into P rates on crop yield and economic returns (2003-2011).

What we learned from this investigation was that on a Mallee clay loam with subsoil limitations, there is no benefit from applying more than 5kg/ha of P per year. This knowledge has helped growers make confident decisions about their P fertiliser requirements and has alleviated fears of inputs and money going to waste.

Over the years, work at the BCG Farming Systems site was supported by a range of government and industry funding partners, including the GrainGrowers, GRDC, Incitec Pivot and DEDJTR (formerly DNRE). In recent years funding has come mainly from BCG members.

With project work at BCG increasing and the priorities of members changing, after fallowing the site in 2014, the BCG Board elected to retire the site in 2015.

Last Tuesday the BCG team joined members and supporters to remove signage, clean-up the site and officially hand it back to the McClelland family.

BCG thanks and acknowledges all supporters of the site over the years, especially the land owners Warrick and Ian McClelland and the farmer Champions for their good will, support and input in making this project a success.